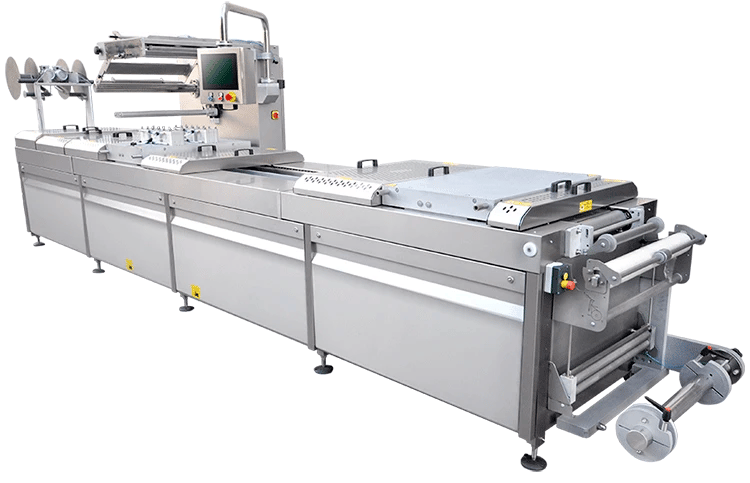

THERMOFORMER

TFF - 1

PACKAGING EXAMPLES

What exactly is a thermoformer?

Thermoforming machines are equipment intended to manufacture products through the thermoforming process. It is the horizontal automatic packaging technology, which is distinguished by the conformation of the container in the machine itself from two reels of different material.

Normally, with this method, the finished products are already achieved, so no further processing is required.

What can a thermoforming machine be used for?

Thermoforming machines can be used in a wide range of industries, including pharmaceutical, non-food and food companies; They also have a wide range of technological applications due to the multiple models available depending on the demands to be met.

Other applications that are growing in popularity include those in the automotive industry, the packaging and packaging business, hardware, and others that are entirely different, such as internal components of household appliances and ship and air travel parts.

Characteristics of a thermoformer

Thermoforming machines are used in two categories: those responsible for the production of consumer items such as home appliances and those responsible for the production of food packaging.

Based on the above, we must consider the following characteristics when selecting a thermoformer:

- High productivity requires high performance.

- Machine parts such as molds, bobbins, and blades must be easy to replace.

- Designs can be easily modified

- Option for simple cleaning and maintenance

Access to machine parts is easy. - Various accessories are available.

How does the thermoforming process work?

Heating, thermoforming and sealing are the three stages of thermoforming.

The heating procedure is carried out by radiators powerful enough to soften the sheet.

After heating, we shape it by thermoforming. This can be classified according to the sheet deformation method (vacuum, pressure or mechanical) or according to the mold cavity method (positive or negative).

When the thermoforming is finished, the containers are filled with the product and the closure is complete. In this way, the final process, namely sealing, takes place.

The containers are cut into pieces by knives to complete the thermoforming process.

The main advantages of thermoforming

If you are still not sure about buying a thermoforming machine, here is a summary of the main advantages it provides:

- It is an effective method for both large and small print runs.

- Various materials can be used, including PAI, PET, ABS, PVC, polycarbonate, and acrylic.

- The molds are cheap and the manufacturing periods are fast.

- It is a suitable technique for prototyping and bulk manufacturing with minimal service costs.

- Color and response time have an economic advantage.

- Depending on the component, it replaces the injection procedure.

- It provides high-quality results that are highly customizable for any client's demands.

In conclusion, it can be stated that the thermoformer is one of the most adaptable machines on the market and that it can be used in practically any type of business to improve the efficiency of the processes.